LEGO® Serious Play® is a method that puts an end to endless discussions and allows all participants to have their say. In this workshop, the participants work co-creatively on tangible models and experience the thinking models of their team colleagues.

What is LEGO® SERIOUS PLAY®?

LEGO® SERIOUS PLAY® (LSP for short) is a well-structured and moderated process that helps teams to work on visions, objectives or strategies. During the workshop, various questions are addressed and answered by each participant and the team in a recurring process. These questions are based on the core question, which has been agreed in advance between the client and the facilitator. The answers are built with the building blocks as metaphors and are given meaning by the “builder” in a short round of introductions.

The four phases

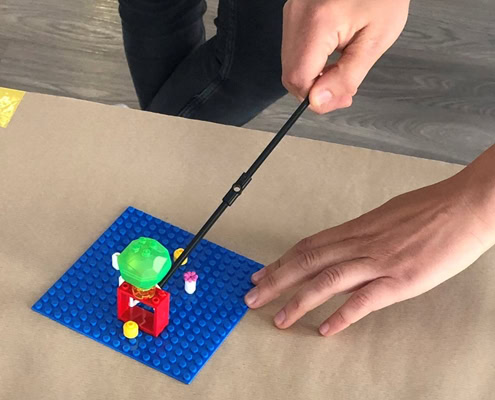

A classic LEGO® SERIOUS PLAY® workshop consists of three phases and can be extended by a fourth phase. In the first phase, the principles and functions are learned. This is why it is also referred to as “skill building”.

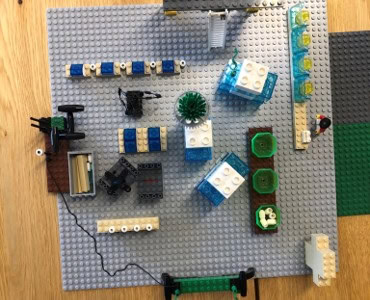

From the second phase onwards, things get practical. Each participant builds their own individual model for a defined question. In the third phase, the models of the individual participants are then merged into a joint model (team model). The team discusses dependencies, influencing factors and practical derivations and consolidates the most important aspects of the individual models. In the optional fourth phase, the team model is expanded to include possible scenarios and influencing factors. This makes it easier to work out overall contexts, challenges or even dependencies. The number of phases depends on the client’s questions and objectives.

The founding fathers of this method were of the opinion that all important results were retained by the participants. Anything that was forgotten was not relevant. However, experience shows that documentation is essential for sharing within the company and for reflection. This is why the documentation is done with photos, videos and, if necessary, a presentation that can be used by management, for example.

What are the benefits and advantages of a LEGO® SERIOUS PLAY® workshop?

LEGO® Serious Play® generates new ideas, improves communication within the team and reduces the time needed to solve problems.

Benefit:

- Development of a vision, objectives, strategy behind which the entire team stands

- Terms are defined and uniformly understood by all participants

- This method helps with team building and the full potential of your team is raised

Advantages:

- Tangible: perspectives and thought models are brought to life and are better remembered through metaphors

- Comprehensible: The building blocks are used for prototyping to discuss models and create facts

- Co-creative: Each participant is 100% integrated into the process and the joint understanding results in the joint further development of the vision, the target image or the strategy

How does an LSP workshop work?

An example of a workshop in which the three phases from skill-building to team model are integrated could look as follows:

| Agenda | Time | Work order |

|---|---|---|

| Skill building | 09:00 | By building low-complexity tasks, participants gain an understanding of mechanics and are introduced to working with LEGO®. After each construction phase, each participant presents their model. The round is concluded with a reflection. After the skill-building, the participants have learned to think in metaphors and storytelling with the models. |

| Individual models – construction stage 1 | 10:45 | The next step is to answer the key question. To do this, individual models are built and presented in the learned mechanics. |

| Lunch break | 12:30 | |

| Team model – construction stage 2 | 13:30 | In the second construction stage, the individual models are combined into a joint model. It is important that the important aspects of the individual models are retained. It is therefore important for each participant to be 100% present in the presentation of the models throughout the entire workshop day. |

| Implementation in concrete steps | 15:00 | The next phase is about deriving concrete measures or further questions from the creative process. The aim is to find a common way forward after the workshop. |

| Reflection | 16:00 | In most cases, the participants experience a new and creative workshop format. With LEGO® SERIOUS PLAY®, exciting aspects become visible on a meta-level and many aha-experiences are collected. These need to be reflected on and learned from as a team. The reflection concludes with a feedback round and the workshop day ends. |

How was this method developed?

Bart Victor and Johan Roos were looking for a method to revolutionize strategy development. Both were professors at the International Institute for Management Development (IMD).

“In our teaching, research and consulting activities, we have repeatedly found that strategy discussions generally focus on objective analysis underpinned by hard figures. The subjective views of managers were usually pushed into the background or even ignored.”

The hour of birth

At the beginning of 1996, Johan Roos was commissioned to develop a strategy program for the top 300 LEGO® managers. After some discussions with LEGO®, he asked Bart Victor for his support. During the development, the two also looked at the LEGO® building blocks. The bricks made it possible to manifest thoughts and give the bricks their own meaning. A limited construction time (time boxing) and speaking time made it possible to involve each workshop participant equally in the development of the result. This was the birth of LEGO® SERIOUS PLAY®.

The method matures

More than twenty iterations of testing, learning and retesting refined this method before it was presented to the public in early 2022. This also resulted in an official product line. Since June 2010, LEGO® SERIOUS PLAY® has been made available for public use under a Creative Commons license. Creative Commons is a non-profit organization that publishes standard license agreements so that rights of use can be granted in a simple way. This has laid the foundation for consultants, workshop moderators and further development in a larger community.

Peter Prütting is a trained LEGO® SERIOUS PLAY® facilitator and moderator. This workshop format is an optional part of the consulting process and can also be booked separately for individual questions on vision, objectives and strategy.

Alle Kontaktmöglichkeiten im Überblick:

Conclusion

“If you want to go fast, then go alone. If you want to go far, go together with others.” LEGO® SERIOUS PLAY® is a very good method for anyone who wants to go far and answer complex questions in a team. The clear and appreciative process allows every participant to have their say. This makes use of all the knowledge in the room. At the same time, the participants become stakeholders, as the shared model contains the aspects that are very important to them. As a facilitator of such workshops, I also find that it helps participants to focus on the model. It is no longer about people, but about models. This makes for honest discussions. LEGO® SERIOUS PLAY® is the method if you want to go far with your team.

Peter Prütting is an expert in value-oriented and digital business development. With over 15 years of sales experience from the perspectives of wholesale, manufacturing, and e-marketplaces, he takes a holistic view. His colleagues value him as a customer-centric and focused leader who guides teams through digital transformation. Away from his daily work, he recharges his batteries by mountain biking.

FAQ – Frequently asked questions

Creative Commons is a non-profit organization that publishes standard license agreements to make it easy to grant rights of use. For example, the LEGO® SERIOUS PLAY® workshop method is freely usable under a Creative Commons license.

Development of a vision, objectives, strategy behind which the whole team stands.

Terms are defined and uniformly understood by all participants. This method helps with team building and the entire potential of your team is raised.

A LEGO® SERIOUS PLAY® workshop ensures that content can be experienced, understood and co-created. In this way, perspectives and thought models are brought to life and are better remembered through metaphors. The building blocks are used for prototyping to discuss models and create facts. Each participant is 100% integrated into the process and the shared understanding results in the joint further development of the vision, the target image or the strategy.

Bart Victor and Johan Roos were looking for a method to revolutionize strategy development. Both were professors at the International Institute for Management Development (IMD). The idea for this workshop format was born in 1996 through a consultancy assignment for LEGO®.

LSP is a well-structured and moderated process that helps teams to work on visions, objectives or strategies. During the workshop, various questions are addressed and answered in a recurring process by each participant and the team. These questions are based on the core question, which has been agreed in advance between the client and the moderator. The answers are built with the building blocks as metaphors and are given meaning by the “builder” in a short round of introductions.

Sources

- Expert for playful workshops, Manuel Grassler: https://manuelgrassler.com/

- Roos, J. and Victor, B. (2018), “How It All Began: The Origins Of LEGO® Serious Play®

- IDM, Business School: International Institute for Management Development

- Sutton-Smith, B. The Ambiguity of Play. Cambridge, MA: Harvard University Press, 1997. Wikipedia, LSP: https://de.wikipedia.org/wiki/LEGO®_Serious_Play